Convert • Fabricate • Manufacture • Supply

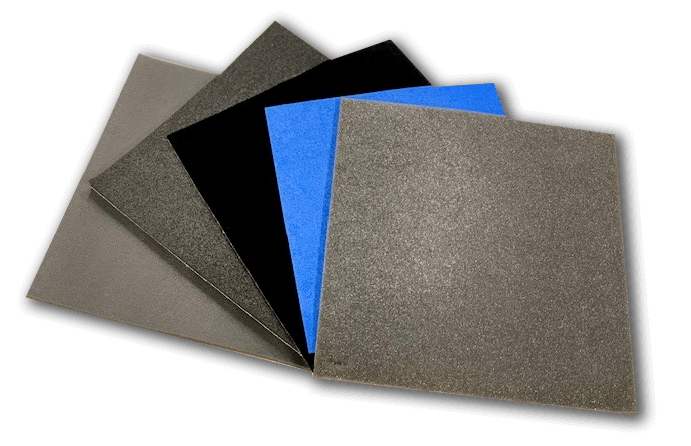

Can-Do Tape is a master converter, fabricator, manufacturer, and supplier of adhesive tapes, foams, foils, cloth and other flexible materials. We stock and manufacture a broad range of pressure sensitive tape, heat seal films and foam products from the highest quality brands within the tape industry. We bring over 100 years of adhesive tape expertise to the table and do what it takes to convert and manufacture jumbo rolls and sheets of adhesive tapes into any custom size, shape or configuration. Our converting capabilities allow us to die cut parts onto rolls, sheets or to individual pieces, kiss cutting, multi-lamination, sheeting, slitting and rewinding rolls to any length and size, custom printing, tabbing, and kitting. Our experienced sales team offers extensive application engineering and will work closely with designers and engineers to solve challenges within product design and manufacturing processes. We also offer reverse engineering and provide prototyping from technical drawings or requirements. Our certification to the ISO 9001 Quality Standard reflects our commitment to excellence.